Aug. 04, 2025

As the oil and gas industry continues to evolve, the need for effective nitrogen production is paramount. Enter the PSA Nitrogen Plant Manufacturer, which has introduced highly efficient nitrogen gas generators to supply the growing demand for nitrogen in diverse applications. One of the primary pain points faced by oil and gas facilities is the reliance on traditional nitrogen supply methods, which can lead to unpredictable costs and supply chain challenges. This has created a scenario where adopting on-site nitrogen generation becomes not only a matter of cost-effectiveness but also operational reliability.

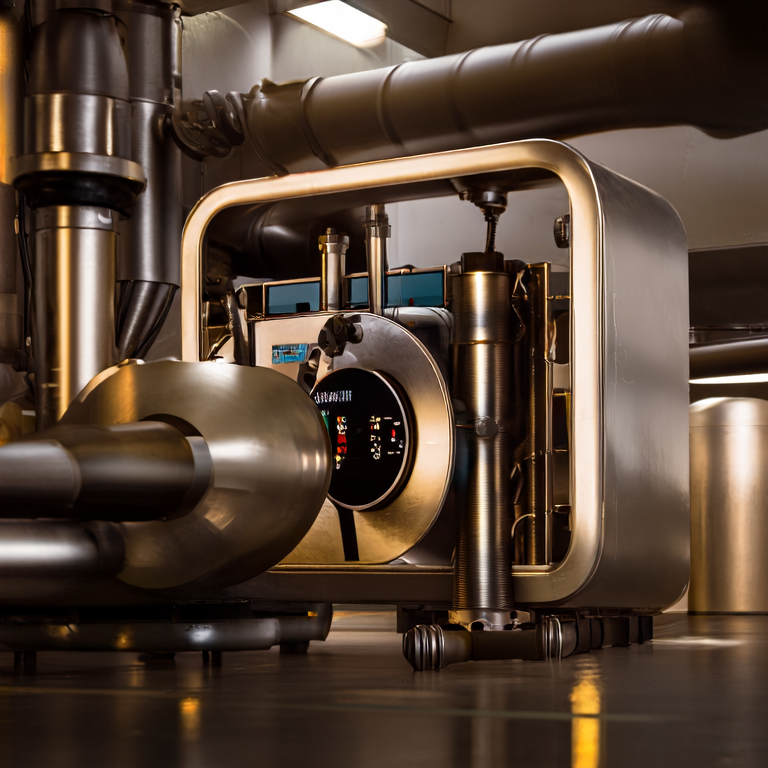

A Pressure Swing Adsorption (PSA) nitrogen plant is an advanced technological solution for generating nitrogen gas. The process operates on the principle of selectively adsorbing oxygen from air, allowing for the extraction of high-purity nitrogen. This method enhances efficiency by utilizing specific adsorbent materials that target oxygen molecules, thereby maximizing nitrogen yield while minimizing waste and energy consumption. According to the Gas Processors Association, PSA systems can achieve nitrogen purities of over 99.99%, making them indispensable for various industrial applications.

PSA nitrogen generators find their utility across several sectors, primarily in oil and gas facilities. They are used for:

The significance of PSA nitrogen generators lies in their manifold advantages. Not only do they deliver a consistent and reliable nitrogen supply, but they also drastically reduce operational costs. For instance, transitioning from a traditional liquid nitrogen supply to an on-site PSA plant can lead to a measurable cost reduction of up to 50% in nitrogen supply expenses, according to data from the American Gas Association. Additionally, facilities can achieve considerable energy savings, with reported decreases in energy consumption by up to 30% compared to older technologies.

For facilities considering the upgrade of their nitrogen supply systems, thorough research is essential. Reading user guides and technical documents can provide deeper insights into the specifics of operation, maintenance, and the benefits of PSA technology. It’s also advisable to consult the manufacturers for tailored solutions that fit specific operational needs.

1. How does a PSA nitrogen generator work? A PSA nitrogen generator employs a two-step process where air is compressed, and oxygen is absorbed by selective adsorbents, allowing nitrogen to pass through and be collected.

2. What industries utilize PSA nitrogen plants? PSA nitrogen plants are primarily used in oil and gas, food packaging, chemical production, and pharmaceutical sectors.

3. What is the purity level achievable by PSA technology? PSA nitrogen generators can achieve purities exceeding 99.99%.

For those looking to better understand PSA nitrogen plants and their operational benefits, we invite you to explore RICH\'s comprehensive resources and trials to see how on-site nitrogen generation can transform your facility\'s processes. Don’t hesitate to reach out for further information or a personalized consultation tailored to your needs.