The Rise of Modular Nitrogen Generation Systems: Scalable and Smart

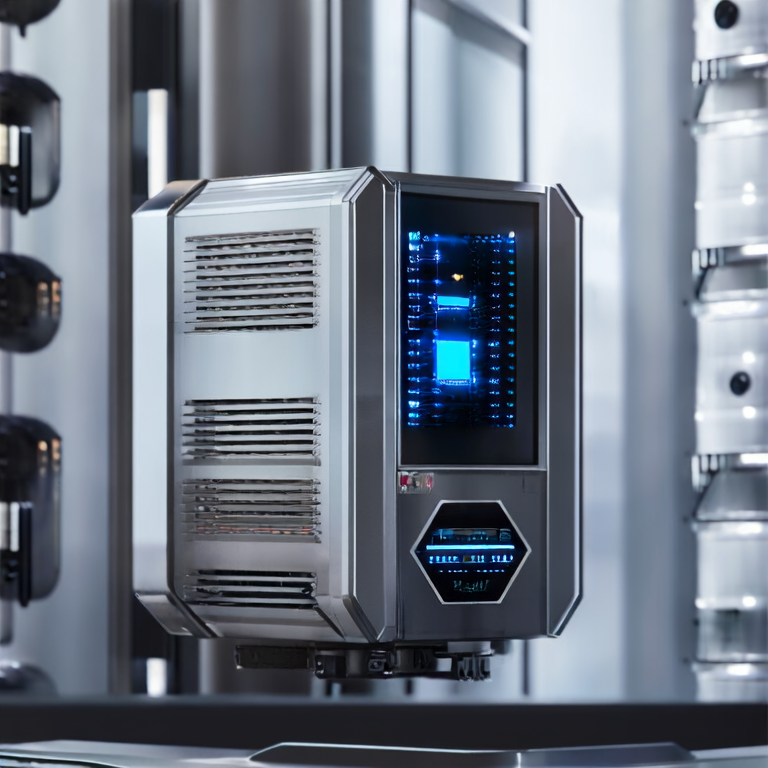

The global industrial landscape is witnessing a significant shift towards sustainable and efficient nitrogen generation solutions. Amidst a surge in demand for reliable nitrogen sources, PSA Nitrogen Plant Manufacturers are stepping up to address critical pain points associated with traditional nitrogen production methods. Industries often face challenges like high operational costs, supply chain disruptions, and environmental concerns. Modular nitrogen generation systems offer scalable and smart solutions, allowing businesses to optimize their nitrogen supply in a more flexible and cost-effective manner.

Key Drivers and Innovations in Nitrogen Generation

Several factors are propelling the growth of modular nitrogen generation systems. First, the emphasis on sustainability is prompting companies to seek eco-friendly alternatives. According to a recent report by the International Energy Agency, industrial energy use, including nitrogen production, contributed 30% to the global energy demand in 2021. Innovations such as advanced pressure swing adsorption (PSA) technology have significantly improved the efficiency of nitrogen generation processes, reducing energy consumption by up to 50% compared to traditional methods.

Emerging Trends in Nitrogen Generation

- Increased Customization: Modular systems can be tailored to meet specific industrial needs, allowing businesses to scale operations efficiently. For instance, RICH\'s modular nitrogen generator can be configured for outputs ranging from 10 to 1000 Nm3/hr, accommodating the varying requirements of users.

- Integration of IoT Technologies: The incorporation of smart sensors in nitrogen generation systems allows for real-time monitoring and adjustments. Reports indicate that IoT-connected devices can enhance operational efficiency by 20% and significantly reduce downtime.

- Focus on Cost Reduction: According to a market analysis by Technavio, the modular nitrogen generator market is expected to grow by 4.56% from 2021 to 2025, driven by the need for reduced operational costs. Companies can save approximately 30% on nitrogen procurement by switching to on-site generation.

Impact on Buyers: Making Informed Decisions

The rise of modular nitrogen generation systems directly impacts buyers by offering them cost-effective and reliable solutions. Businesses can now avoid long-term contracts associated with bulk nitrogen purchases and instead, generate their own nitrogen on-site. Coupled with the flexibility to adjust production levels, buyers can manage their nitrogen requirements dynamically, ensuring they are not overspending while still meeting operational demands.

Practical Suggestions for Adopting Modular Systems

- Conduct a Needs Assessment: Before transitioning to a modular nitrogen generation system, businesses should evaluate their specific nitrogen usage needs and operational demands.

- Partner with Experienced Manufacturers: Collaborate with reliable Nitrogen Gas Generator Manufacturers, such as RICH, who can provide expert guidance on system selection and customization.

- Implement Training Programs: Ensure that staff are well-trained in operating and maintaining newly integrated nitrogen generation systems to maximize efficiency and minimize errors.

Frequently Asked Questions (FAQ)

- What is a modular nitrogen generation system? It is a flexible nitrogen production setup that can be easily adjusted according to the specific requirements of different industries.

- How does pressure swing adsorption (PSA) technology work? PSA technology separates nitrogen from air under pressure, providing a continuous and consistent flow of high-purity nitrogen.

- Can modular nitrogen systems save costs? Yes, they significantly reduce the costs associated with purchasing bulk nitrogen and offer scalable solutions to meet varying demands.

As industries continue to adapt to changing operational requirements, the adoption of modular nitrogen generation systems is likely to increase, forging a path towards a more efficient and self-reliant future.