Jul. 25, 2025

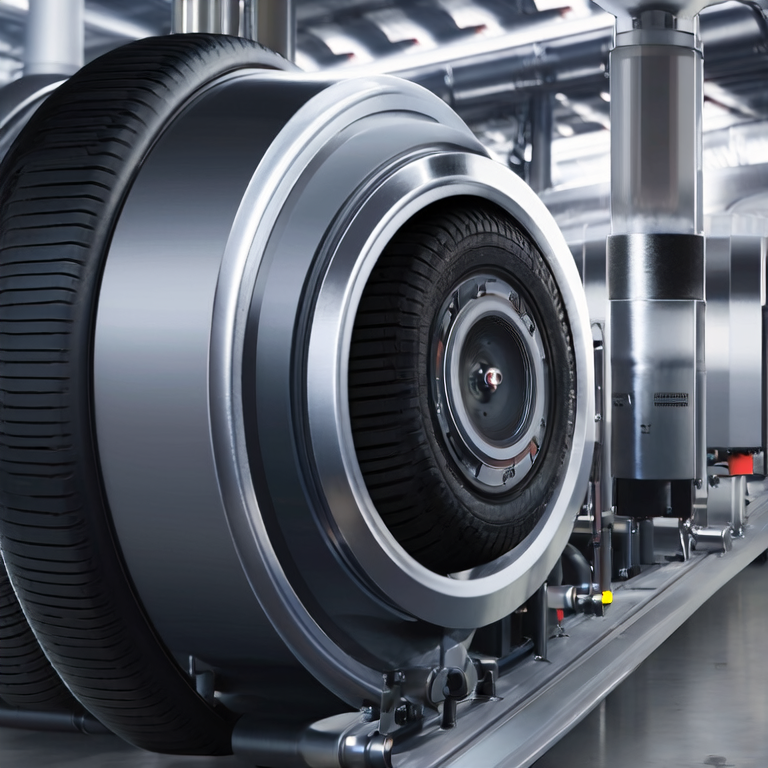

When it comes to tire maintenance and safety, quality is paramount. Many vehicle owners deal with issues such as fluctuating tire pressure, reduced fuel efficiency, and premature tire wear. These problems stem from moisture-laden regular air that enters tires. The solution? Utilizing on-site nitrogen from a PSA Nitrogen Plant Manufacturer to maintain optimal tire quality. Nitrogen, as an inert gas, reduces oxidation and maintains constant pressure, promoting better vehicle performance. In this article, we will explore common user problems, how nitrogen impacts tire integrity, a detailed implementation process, and personal stories that illustrate the benefits.

Many drivers may not realize that regular air contains approximately 78% nitrogen but also includes about 21% oxygen and 1% other gases, like moisture. This combination can lead to fluctuating tire pressure due to temperature changes, increasing the probability of blowouts and decreasing fuel efficiency by as much as 3%. Additionally, a study shows that tires filled with nitrogen maintain proper pressure up to 30% longer than those filled with regular air, improving overall tire longevity.

Before you dive into the process of using on-site nitrogen, it’s essential to gather the following tools and materials:

Begin by positioning your nitrogen gas generator in a well-ventilated area, ensuring you follow the manufacturer\'s setup instructions.

Next, connect the nitrogen generator to the tire inflator using the appropriate hoses. Make sure there are no leaks by performing a quick pressure test.

For best results, you may want to deflate the tires to around 10-15 psi. Use the tire deflator tool carefully to avoid damaging the valve.

Attach the tire inflator to the valve stem, ensuring a tight seal. Turn on the generator and fill the tires with nitrogen until the desired pressure is reached, typically around 30-35 psi.

Finally, use the digital pressure gauge to ensure that tire pressure remains consistent. Regular checks can help prevent drops in pressure due to temperature fluctuations, ensuring that your tires live a longer lifespan.

1. Insufficient Inflation: If tires aren’t filled to the recommended pressure, check for leaks in the connections.

2. Moisture Contamination: Ensure that the nitrogen source is free of moisture during the process and invest in a good quality nitrogen generator.

3. Over-Inflation: Always monitor tire pressure post-inflation to avoid potential tire damage.

Jennifer, an avid road trip enthusiast, started using nitrogen for her SUV tires last summer. She reported an impressive 15% improvement in her gas mileage during long drives, which translated into about 50 additional miles per tank. “I couldn’t believe the difference nitrogen made,” she said. “Not only did my tires feel more stable, but the wear was noticeably reduced, allowing me to save on costly replacements.”

Overall, utilizing on-site nitrogen for your tires can enhance stability, fuel efficiency, and prolong their life significantly. We recommend regular monitoring and filling up with nitrogen to maintain peak performance. By working with trusted Nitrogen Gas Generator Manufacturers, you ensure a reliable supply of high-quality nitrogen, ultimately elevating your vehicle\'s performance.

What are the benefits of using nitrogen in tires?

Using nitrogen in tires helps maintain consistent pressure, reduces tire wear and tear, and enhances fuel efficiency.

How often should I fill my tires with nitrogen?

It’s recommended to check the pressure monthly and re-fill as needed, especially before long trips.

Can I mix regular air with nitrogen?

While it is not ideal, mixing can still offer benefits; however, it’s best to have tires filled purely with nitrogen for optimal results.